Hoe Transformatoren fan epoksyhars cast droech type massaproduksje revolúsjonearje yn ‘e produksjesektor

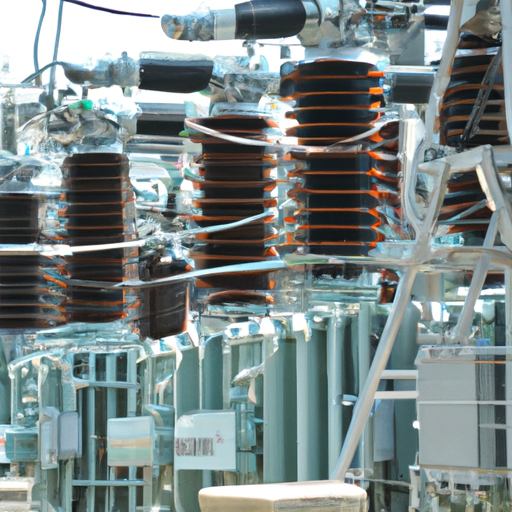

De produksje yndustry ûndergiet in revolúsje mei de ynfiering fan epoksy hars getten droech type Transformatoren. Dizze Transformators revolúsjonearje massaproduksje troch in effisjintere en kosteneffektivere manier te leverjen om produkten te produsearjen.

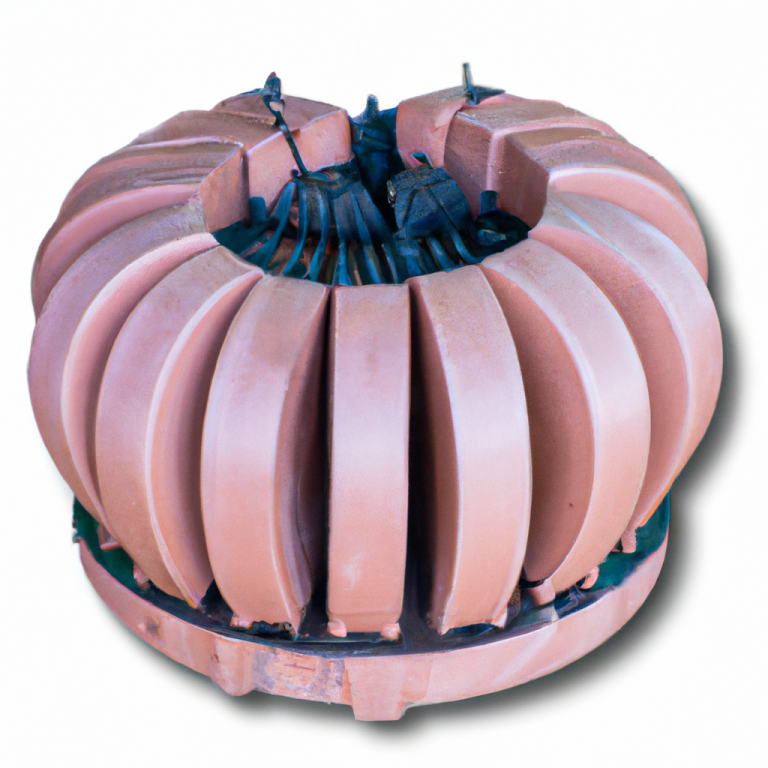

Epoksyhars getten droege type Transformatoren wurde makke fan in kombinaasje fan epoksyhars en droege type Transformatorkomponinten. Dizze kombinaasje makket in lichtgewicht, duorsume en heul effisjinte Transformator dy’t ideaal is foar massaproduksje. De epoksyhars getten droech type Transformator is ek folle rendiger as tradisjonele Transformators, wêrtroch it in oantreklike opsje is foar fabrikanten. Dit makket it ideaal foar massaproduksje, om’t it fluch en maklik kin wurde ynstalleare op in ferskaat oan lokaasjes. Derneist is de epoksyhars-getten droege type Transformator folle betrouberer dan tradisjonele Transformators, wat betsjuttet dat fabrikanten derop kinne fertrouwe om konsekwinte resultaten te produsearjen.

| Type | Nominearre kapasiteit KVA | Voltage kombinaasje KV | No-load ferlies W | Load ferlies W | No-load current % | Kortslutingsimpedânsje % |

| SC12-30 | 30 | 6,6.3,6.6,10,11/0.4 | 150 | 710 | 2.0 | 4.0 |

| SC12-50 | 50 | 6,6.3,6.6,10,11/0.4 | 215 | 1000 | 2.0 | 4.0 |

| SC12-80 | 80 | 6,6.3,6.6,10,11/0.4 | 295 | 1380 | 1.5 | 4.0 |

| SC12-100 | 100 | 6,6.3,6.6,10,11/0.4 | 320 | 1570 | 1.5 | 4.0 |

| SC12-125 | 125 | 6,6.3,6.6,10,11/0.4 | 375 | 1850 | 1.3 | 4.0 |

| SCB12-160 | 160 | 6,6.3,6.6,10,11/0.4 | 430 | 2130 | 1.3 | 4.0 |

| SCB12-200 | 200 | 6,6.3,6.6,10,11/0.4 | 495 | 2530 | 1.1 | 4.0 |

| SCB12-250 | 250 | 6,6.3,6.6,10,11/0.4 | 575 | 2760 | 1.1 | 4.0 |

| SCB12-315 | 315 | 6,6.3,6.6,10,11/0.4 | 705 | 3470 | 1.0 | 4.0 |

| SCB12-400 | 400 | 6,6.3,6.6,10,11/0.4 | 785 | 3990 | 1.0 | 4.0 |

| SCB12-500 | 500 | 6,6.3,6.6,10,11/0.4 | 930 | 4880 | 1.0 | 4.0 |

| SCB12-630 | 630 | 6,6.3,6.6,10,11/0.4 | 1070 | 5880 | 0.85 | 4.0 |

| SCB12-630 | 630 | 6,6.3,6.6,10,11/0.4 | 1040 | 5960 | 0.85 | 6.0 |

| SCB12-800 | 800 | 6,6.3,6.6,10,11/0.4 | 1210 | 6960 | 0.85 | 6.0 |

| SCB12-1000 | 1000 | 6,6.3,6.6,10,11/0.4 | 1410 | 8130 | 0.85 | 6.0 |

| SCB12-1250 | 1250 | 6,6.3,6.6,10,11/0.4 | 1670 | 9690 | 0.85 | 6.0 |

| SCB12-1600 | 1600 | 6,6.3,6.6,10,11/0.4 | 1960 | 11700 | 0.85 | 6.0 |

| SCB12-2000 | 2000 | 6,6.3,6.6,10,11/0.4 | 2440 | 14400 | 0.7 | 6.0 |

| SCB12-2500 | 2500 | 6,6.3,6.6,10,11/0.4 | 2880 | 17100 | 0.7 | 6.0 |

It gebrûk fan epoksyhars getten droege type Transformatoren yn massaproduksjeprosessen kin in oantal foardielen leverje. Dizze Transformators binne ûntworpen om lichtgewicht, duorsum en kosten-effektyf te wêzen, wêrtroch’t se in ideale kar binne foar in protte yndustriële tapassingen.

Ien fan ‘e primêre foardielen fan it brûken fan epoksyhars getten droege type Transformatoren is har fermogen om enerzjyferbrûk te ferminderjen. Dizze Transformators binne ûntworpen om heul effisjint te wêzen, wat betsjuttet dat se minder enerzjy hawwe om te operearjen dan tradisjonele Transformators. Dit kin liede ta signifikante kostenbesparring op ‘e lange termyn, en ek in fermindering fan’ e miljeu-ynfloed fan it produksjeproses.

In oar foardiel fan it brûken fan epoksyhars cast droege type Transformatoren is har fermogen om ekstreme temperatueren te wjerstean. Dizze Transformators binne ûntworpen om temperatueren oant 150ºC te wjerstean, sadat se geskikt binne foar gebrûk yn in breed skala oan yndustriële tapassingen. Dit makket se ideaal foar gebrûk yn massaproduksjeprosessen, om’t se de hege temperatueren dy’t ferbûn binne mei dizze prosessen kinne omgean. Dizze Transformators binne ûntworpen om resistint te wêzen tsjin korrosje en oare omjouwingsfaktoaren, wat betsjuttet dat se kinne wurde brûkt yn in ferskaat oan ferskillende omjouwings sûnder eangst foar mislearring. Dit makket se ideaal foar gebrûk yn massaproduksjeprosessen, om’t se kinne wurde fertroud om konsekwinte prestaasjes yn ‘e rin fan’ e tiid te jaan. Dizze Transformators binne ûntworpen om lichtgewicht, duorsum en kosten-effektyf te wêzen, wêrtroch’t se in ideale kar binne foar in protte yndustriële tapassingen. Derneist binne se ûntworpen om heul effisjint en betrouber te wêzen, wat betsjuttet dat se op ‘e lange termyn wichtige kostenbesparring en miljeufoardielen kinne leverje.

The use of epoxy resin cast Dry type transformers in mass production manufacturing processes can provide a number of benefits. These transformers are designed to be lightweight, durable, and cost-effective, making them an ideal choice for many industrial applications.

One of the primary benefits of using epoxy resin cast Dry type transformers is their ability to reduce energy consumption. These transformers are designed to be highly efficient, meaning they require less energy to operate than traditional transformers. This can lead to significant cost savings in the long run, as well as a reduction in the environmental impact of the manufacturing process.

Another benefit of using epoxy resin cast Dry type transformers is their ability to withstand extreme temperatures. These transformers are designed to be able to withstand temperatures up to 150°C, making them suitable for use in a wide range of industrial applications. This makes them ideal for use in mass production processes, as they can handle the high temperatures associated with these processes.

Finally, epoxy resin cast Dry type transformers are also designed to be highly reliable. These transformers are designed to be resistant to corrosion and other environmental factors, meaning they can be used in a variety of different environments without fear of failure. This makes them ideal for use in mass production processes, as they can be relied upon to provide consistent performance over time.

Overall, the use of epoxy resin cast Dry type transformers in mass production manufacturing processes can provide a number of benefits. These transformers are designed to be lightweight, durable, and cost-effective, making them an ideal choice for many industrial applications. Additionally, they are designed to be highly efficient and reliable, meaning they can provide significant cost savings and environmental benefits in the long run.