Exploring the Benefits of Using a 3 Phase Dry type transformer for Dyn11, Yyno, and YNd11 Applications

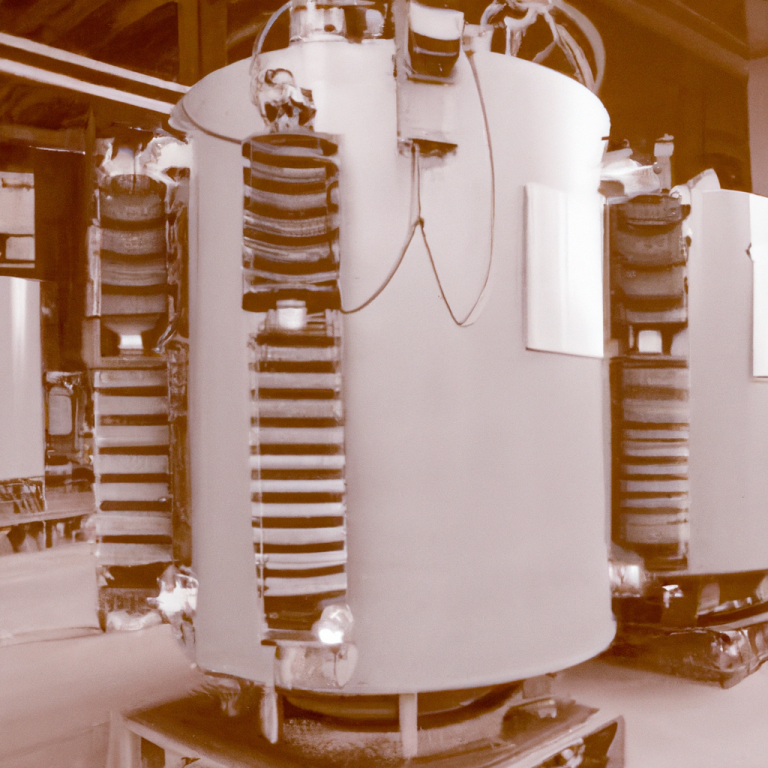

A three-phase Dry type transformer is a reliable and efficient device used to convert electrical energy from one voltage level to another. It is commonly used in industrial and commercial applications, such as Dyn11, Yyno, and YNd11. This type of transformer offers several advantages over other types of transformers, making it an ideal choice for these applications.

One of the primary benefits of using a three-phase Dry type transformer is its high efficiency. This type of transformer is designed to minimize energy losses, resulting in a more efficient operation. This can help reduce energy costs and improve the overall performance of the system. Additionally, the transformer is designed to be more reliable than other types of transformers, making it a great choice for applications that require a high degree of reliability.

Another advantage of using a three-phase Dry type transformer is its low maintenance requirements. This type of transformer does not require any lubrication or other maintenance, making it a cost-effective choice for applications that require minimal maintenance. Additionally, the transformer is designed to be resistant to corrosion and other environmental factors, making it a great choice for outdoor applications.

Finally, a three-phase Dry type transformer is a great choice for applications that require a high degree of safety. This type of transformer is designed to be safe to use and is UL listed, meaning it meets the highest safety standards. Additionally, the transformer is designed to be resistant to short-circuiting, making it a great choice for applications that require a high degree of safety.

Overall, a three-phase Dry type transformer is an ideal choice for Dyn11, Yyno, and YNd11 applications. This type of transformer offers several advantages over other types of transformers, including high efficiency, low maintenance requirements, and a high degree of safety. Additionally, the transformer is designed to be resistant to corrosion and other environmental factors, making it a great choice for outdoor applications.

Understanding the Different Types of 3 Phase Dry type transformers and Their Uses

Three-phase Dry type transformers are a type of Electrical transformer that is used to convert electrical power from one voltage level to another. They are commonly used in industrial and commercial applications, as well as in residential settings. These transformers are designed to be used in dry, non-hazardous environments, and are typically constructed with a sealed enclosure to protect the internal components from dust, moisture, and other environmental factors.

The three main types of three-phase Dry type transformers are core form, shell form, and autotransformers. Core form transformers are the most common type of three-phase Dry type transformer. They are constructed with a core of stacked laminations of steel, which are insulated from each other. The primary and secondary windings are wound around the core, and the entire assembly is then placed in a sealed enclosure. Core form transformers are typically used in applications where the load is relatively constant, such as in industrial settings.

Shell form transformers are similar to core form transformers, but they are constructed with a single core of steel laminations. The primary and secondary windings are wound around the core, and the entire assembly is then placed in a sealed enclosure. Shell form transformers are typically used in applications where the load is variable, such as in residential settings.

Autotransformers are a type of three-phase Dry type transformer that is used to convert voltage levels between two different circuits. They are constructed with a single winding that is connected to both the primary and secondary circuits. Autotransformers are typically used in applications where the load is variable, such as in residential settings.

Three-phase Dry type transformers are an essential component of any electrical system, and they are used in a variety of applications. They are designed to be used in dry, non-hazardous environments, and are typically constructed with a sealed enclosure to protect the internal components from dust, moisture, and other environmental factors. Core form, shell form, and autotransformers are the three main types of three-phase Dry type transformers, and each type is used in different applications depending on the load requirements.

Comparing the Quality and Performance of China Manufactured 3 Phase Dry type transformers

The quality and performance of China manufactured 3 phase Dry type transformers is an important consideration for many businesses. As the demand for these products increases, it is important to understand the differences between the various manufacturers and the quality of their products. This article will provide an overview of the quality and performance of China manufactured 3 phase Dry type transformers, and compare them to other manufacturers.

When it comes to quality, China manufactured 3 phase Dry type transformers are generally considered to be of a high standard. The materials used in their construction are of a high quality, and the manufacturing process is highly regulated. This ensures that the transformers are reliable and durable. Additionally, the transformers are tested to ensure that they meet the required safety standards.

In terms of performance, China manufactured 3 phase Dry type transformers are known for their efficiency. They are designed to provide a high level of power output, while consuming less energy than other types of transformers. This makes them ideal for applications where energy efficiency is a priority. Additionally, they are designed to be able to handle a wide range of voltages and frequencies, making them suitable for a variety of applications.

When compared to other manufacturers, China manufactured 3 phase Dry type transformers are generally considered to be of a higher quality and performance. They are reliable, efficient, and able to handle a wide range of voltages and frequencies. Additionally, they are tested to ensure that they meet the required safety standards. This makes them an ideal choice for businesses looking for a reliable and efficient transformer.