Why choose MV/LV compact substations

- Compact structure

- Strong complete set

- Environmentally-friendly production

- Safe and reliable operation

- Easy maintenance

- Beautiful appearance

Latest developments: Expandingthe portfolio

Putuo Electric introduces FreeCombination™Technologythat combines various types of transformer production into one united mechanism to improve production efficiency, stabilize product quality, and enhance product performance.

All these transformers can be designed, customized, and supplied with a wide variety of accessories, as required.

Putuo MV/LV compact substations are able to reach 3150 kVA and operating voltages of up to 40.5 kV. This product is a kind of new type complete set equipment which could achieve energy saving and cost reducing in urban and rural substation construction and transformation.

Reliable solutions for all applications

Putuo Elecric has expertise in producing transformers for optimum space utilization, special requirements, and the most demanding conditions, has become one of the global leaders in power technologies, providing the broadest experience in all applications, ranges, and customized projects:

- Industrial & mining enterprises

- Resident sub district

- Docks

- Parks

- Streets

- Public places

- Residential areas

- Ring power supply

- Terminal power supply

- Railway station

- Road electricity supply

Our technology: What makes us different?

Putuo Electric uses the most advanced production technologies and the most demanding control systems to guarantee the highest product quality and total product reliability.

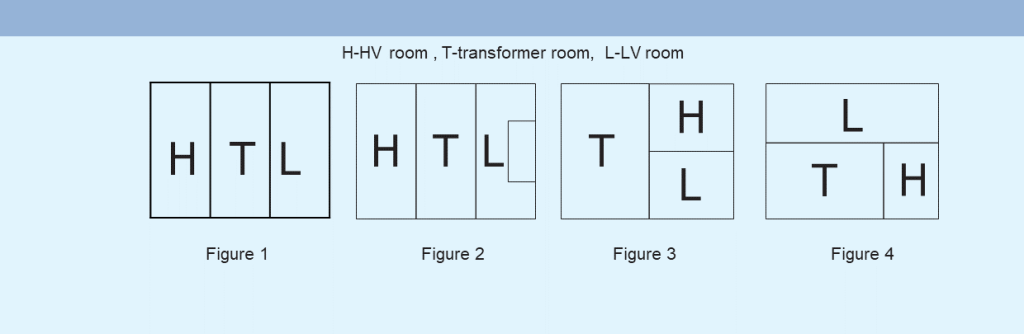

1. The product is composed of medium voltage power distribution equipment, transformer and low voltage power distribution equipment, divided into three functional compartments, which are medium voltage room, transformer room and low voltage room. The medium and low voltage rooms are fully functioned. Preliminary power distribution system at medium voltage side can be arranged in looped network power supply, terminal power supply, dual power supply and other power supply methods. Medium voltage metering components can be installed to meet medium voltage metering requirements. The transformer room could be S11,S11-M R and other low loss Oil immersed transformer and dry transformer. Transformer room is equipped with automatic start forced air cooling system and lighting system, The low voltage room could use panel or cabinet structure according to the user’s requirements to constitute the required power supply program, with power distribution, lighting power distribution, reactive power compensation, power metering and power measurement functions, to meet the user’s different requirements, to facilitate user’s power supply management and improve power supply quality.

2. Medium and low voltage rooms are arranged compact and reasonable, convenient to operate and overhaul. Medium voltage circuit breaker has anti-misoperation interlock function. According to the user’s requirements. the transformer could access transformer main door from the track, ln addition, the transformer door is equipped with labyrinth ventilation. Every room is equipped with automatic lighting device. in addition, the performance of selected elements for medium and low voltage switchgears has features of reliable performance. simple operation and convenient overhaul. The top cover of substation is dual-layer insulation structure, which could reduce solar radiation. The surrounding eaves have ventilation holes, forming convection function with every functional room, to facilitate ventilation and heat dissipation, The bottom base is steel structure. with sufficient strength and rigidity.

3. Natural and forced ventilation two cooling methods are adopted to keep good ventilation and cooling performance. Transformer room has temperature controller which could automatically control the transformer temperature, ensuring full capacity operation of the transformer.

4. Depending on application conditions, different structural forms and materials could be used to meet different use requirements and ensure normal operation of the substation, The enclosure of substation could be made of ordinary steel, stainless steel, aluminum alloy plate, colored composite plate, partially or completely going through surface treatment, so that the shell could have long-term outdoor use conditions, ensuring waterproof, dustproof performance, with long service life and beautiful appearance. The basic structure can be roughly divided into:

-General substation which is made of ordinary steel plate

-High anti-corrosion type substation which is made of stainless steel or aluminum alloy plate

-Heat preservation and insulation type substation which is made of colored composite plate

-Other kinds of substations

5. Incoming and outgoing line are cables, and we also can use other types according to customer’s special requirements.

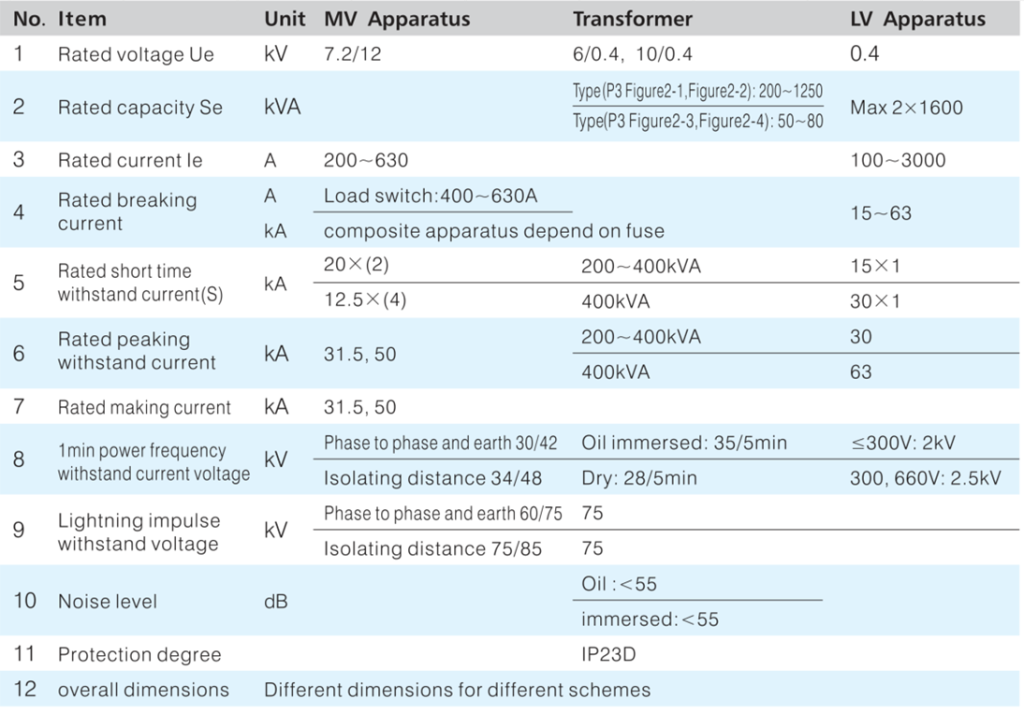

Main technical parameters: to be customized designed

Our values

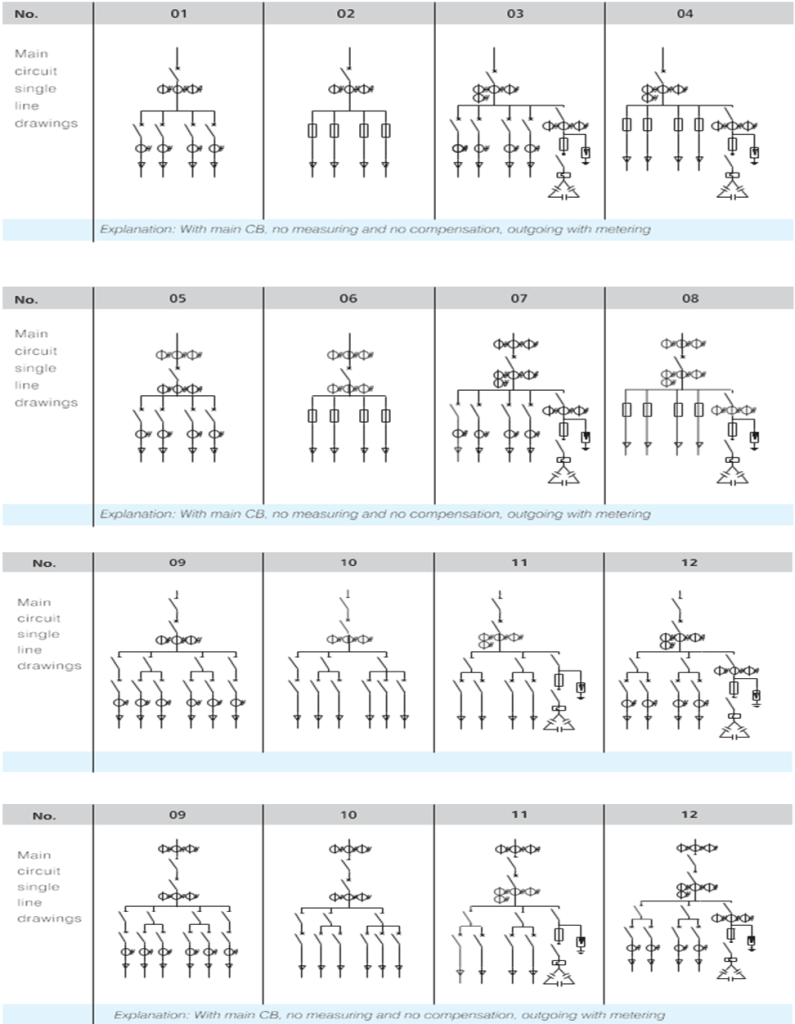

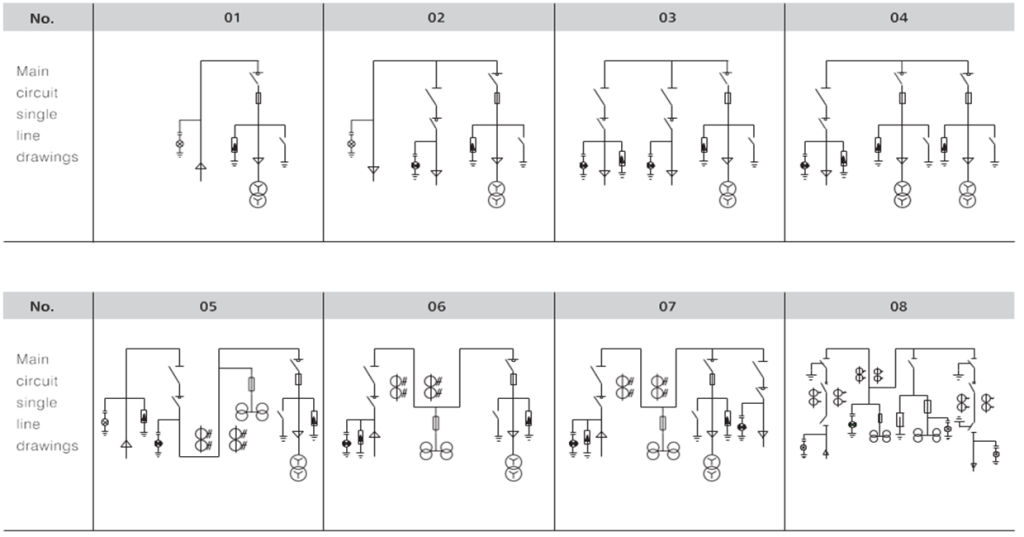

Main circuit schemes can be custom-designed according to customer requirement

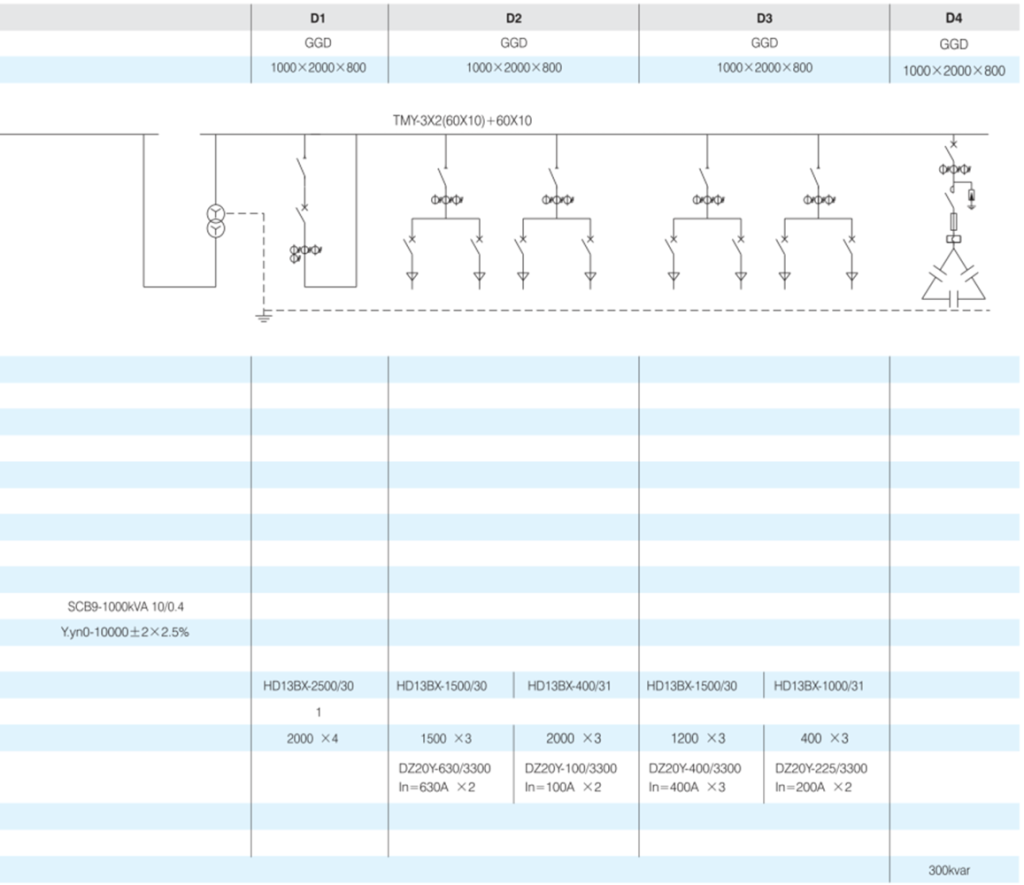

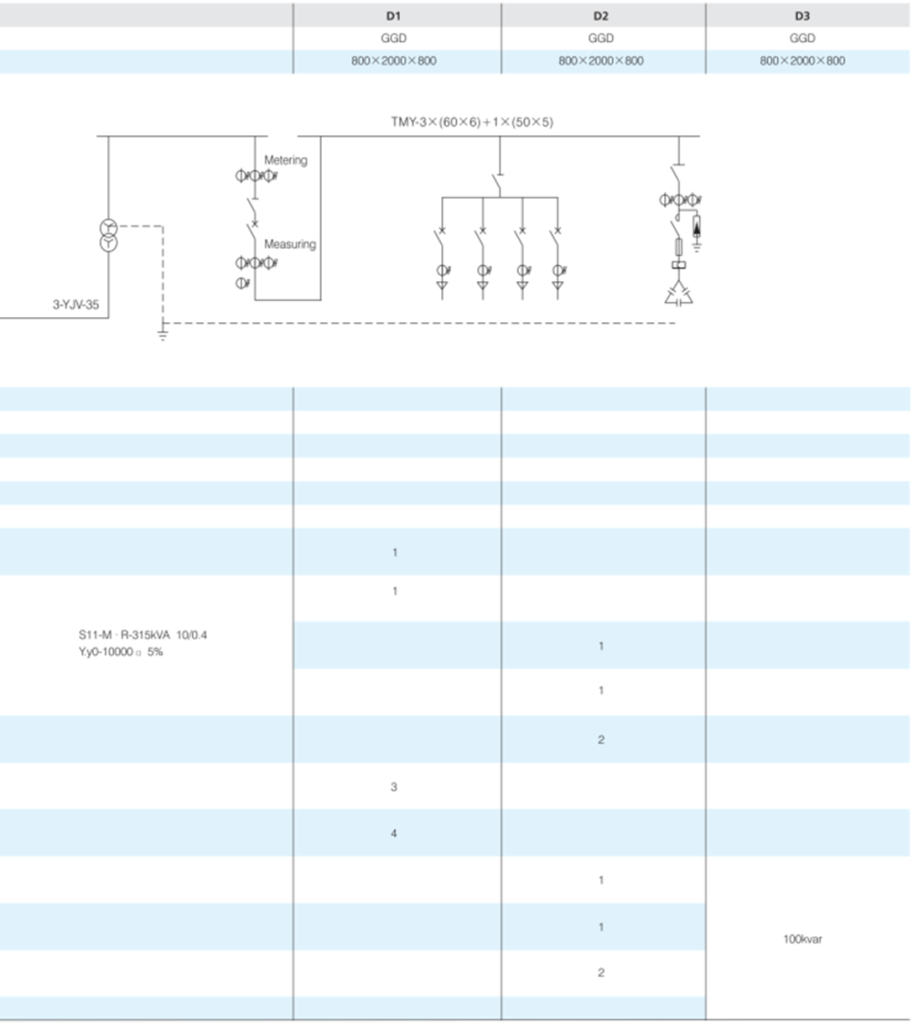

LV main circuit schemes

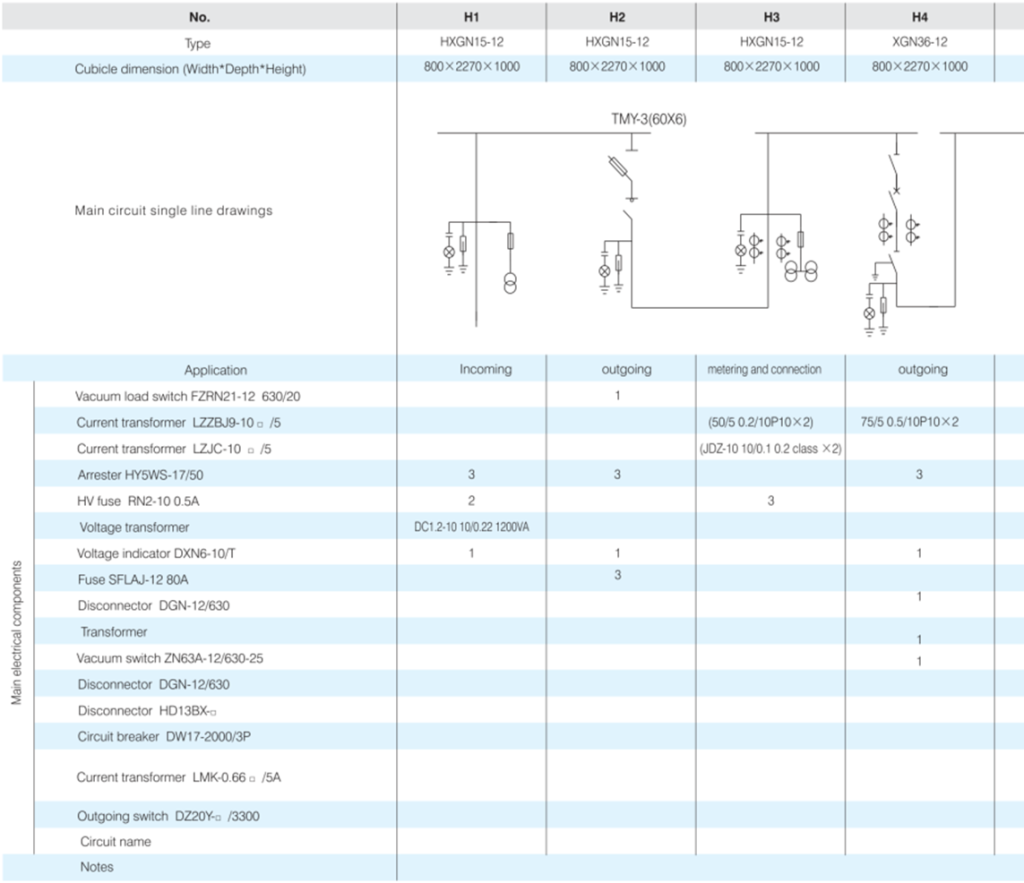

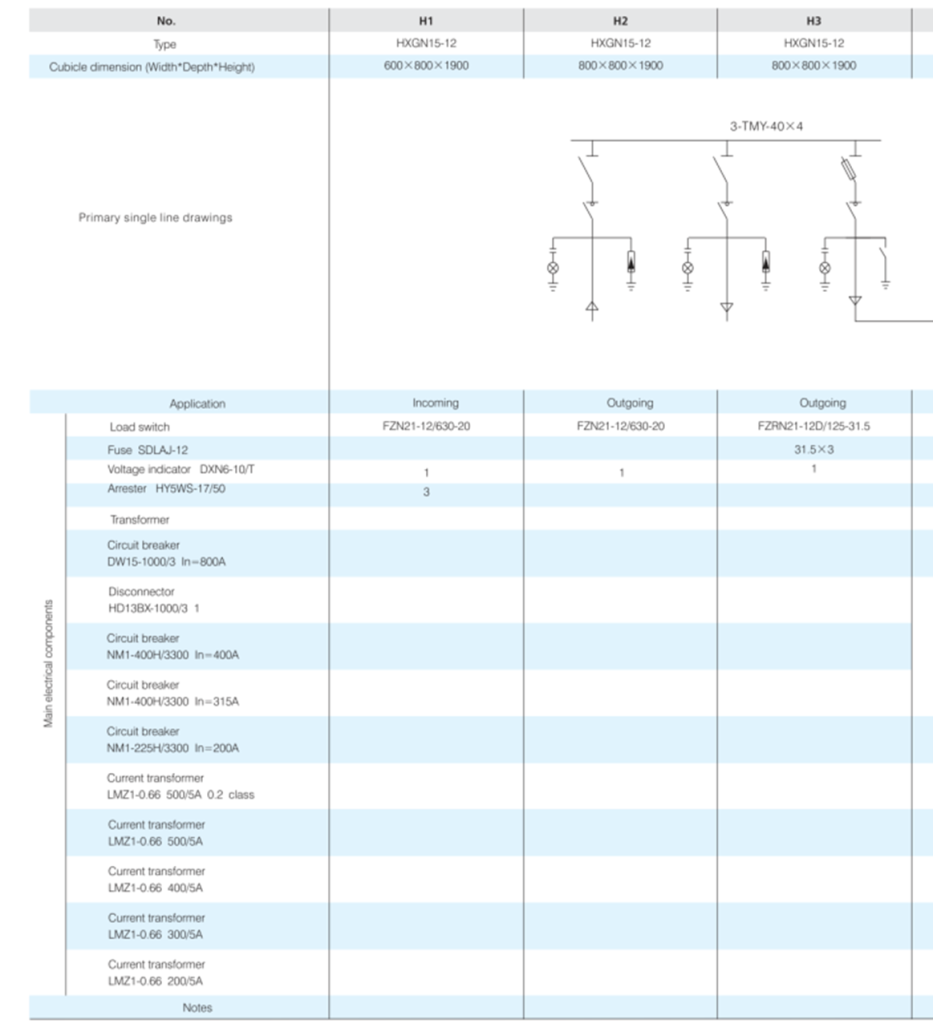

HV main circuit schemes

Various connection scheme plans available to customer requirement

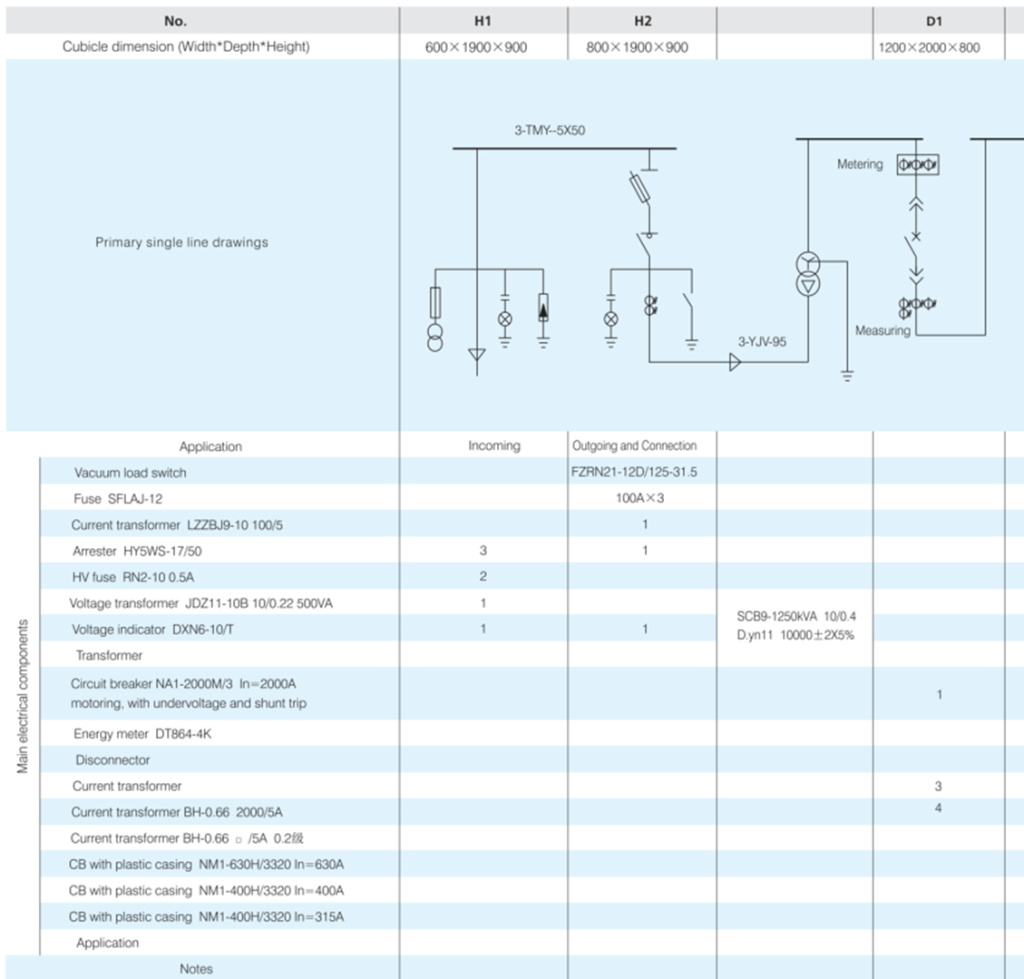

> 1. Cable incoming, high supplying and high metering scheme

—Continue from above table

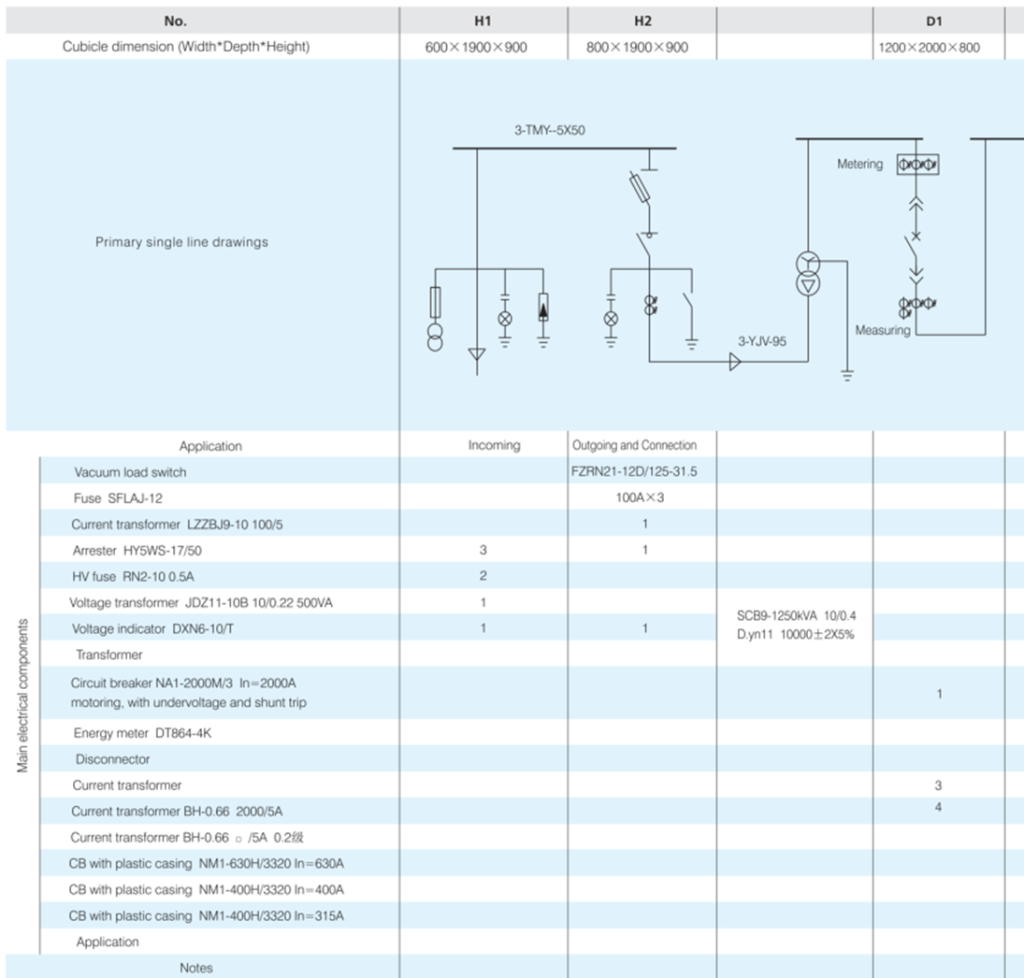

> 2. Cable incoming, high supplying and high metering scheme

— Continue from above table

> 3. Cable incoming, Ring network power supply, high supplying and low metering scheme

— Continue from above table

Testing and logistics: Make sure every product reaches our customer with high quality

All transformers are manufactured to the most stringent quality control standards in order to guarantee the full reliability of the product

Routine test

All transformers are 100% routine tested:

• Voltage ratio measurement and check of phase displacement

• Induced over-voltage withstand test

• Partial discharge measurements

• No load loss and current measurement

• Measurements of windings resistances

• Load loss and short circuit impedance measurements

• Leak test

Type tests

Performed according to customer requirements:

• Temperature rise test

• Lightning impulse test

Special tests

Performed according to customer requirements:

• Measuring zero-sequence impedance

• Noise level test

• Measuring insulation resistance

• Measuring of harmonics of the no-load current

• Measuring of the parallel capacity of windings and tag ∂

• Anti-corrosion protection checking

• Short circuit test & Vibration test

Logistics and services

Once the transformer is successfully tested, the product is ready for shipping, either by truck or sea freight.

As a manufacturer, Putuo Electric understands the relevance of what logistics represents to the customers. This is one of the reasons why Putuo Electric has developed a large and qualified network of suppliers with the same values and targets.

Putuo Electric takes care of all official documentation, depending on the final destination and delivery terms.

Different packaging for special applications or conditions

• Standard packaging

• Crate packaging

• Sea-worthy packaging

Putuo Electric has a long experience in arranging special transport, as and when it is required.

In addition, Putuo Electric’s global presence ensures the best, local, and after-sales service.

Working with Putuo Electric, you have access to a worldwide service with a full range of products and solutions, access to production facilities using the most up to date technologies that provides the highest quality for standard and specially made products and solutions. Our warranty provides “Life-long & 7/24” quality and service.