Why choose dry-type: Safe and environmental friendly transformers

• Reduced environmental contamination

• 0-risk of leakage of flammable or contaminating substances

• Environmentally-friendly production

• Well-suited to dump and contaminated areas

• Non-flammable and self-extinguishing

• High resistance to short circuits

• High capacity to support overloads

• High performance in dealing with seismic phenomenon

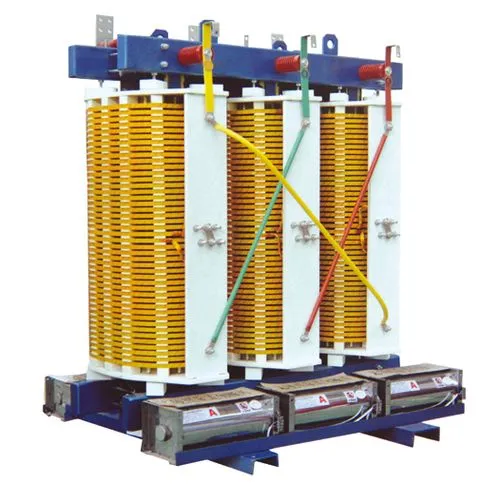

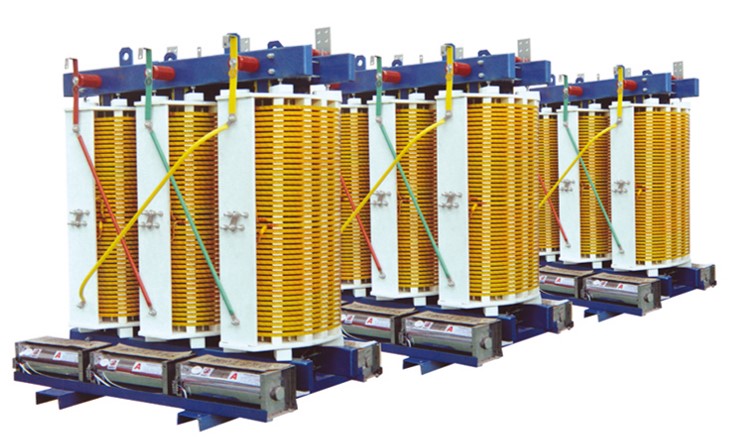

Latest developments: Expandingthe portfolio

Putuo Electric introduces FreeCombination™Technologythat combines various types of transformer production into one united mechanism to improve production efficiency, stabilize product quality, and enhance product performance.

All these transformers can be designed, customized, and supplied with a wide variety of accessories, as required.

Putuo VPI Dry-type Transformers are able to reach 20000 kVA and operating voltages of up to 40.5 kV. This product offers savings on civil works, fire systems, insurance fees, site installation, shorter cables, and maintenance.

Reliable solutions for all applications

Putuo Elecric has expertise in producing transformers for optimum space utilization, special requirements, and the most demanding conditions.

Putuo Elecric is one of the global leaders in power technologies, providing the broadest experience in all applications, ranges, and customized projects:

- drives

- wind

- solar

- solar marine

- solar railways

- solar power plants

- solar utilities

- solar building

- solar chemical and pharmaceutical

- metal and mining

- pulp and paper

- oil and gas

- cement

- water

- industry

- infrastructure

Our technology: What makes us different?

Putuo Electric uses the most advanced production technologies and the most demanding control systems to guarantee the highest product quality and total product reliability.

- The magnetic core has a miter step joint to ensure optimum performance and minimum sound levels by using step lap technology. The magnetic steel is cut to length sequentially and automatically stacked. This ensure dimensional accuracy and single sheet interlacing within the full stack.

- The high voltage winding has a multilayer structure with copper (or aluminum) wire and strip and layer insulation. The high voltage winding has also continuous disc structure with copper (or aluminum) strip. Windings are impregnated under vacuum condition. Transient analysis has been performed to verify the electrical stress distribution through the windings confirming highest strength in our design.

- The low voltage winding are made of conductor foil (copper or aluminum) and insulating foil. The axial cooling dusts are set to provide more efficient heat dissipating.

- The winding process is to wind inner winding first , and then wind the outer winding on the ready inner winding directly. Both inner and outer winding are conducted VPI (vacuum pressure impregnation) process, the winding will become a compact and ro-bust winding to withstand sudden short circuit force.

- In Putuo Electric factories, the whole tendering, design, and production process is controlled and planned with sophisticated software. This ensures the highest productivity and reduced production time while maintaining the highest quality standards.

Putuo Electric manufactures various types of VPI Dry type transformers:

Our values: All this process is certified under the strictest quality standards

Design

- Guarantee of accurate temperature rise in windings; in case of enclosure IP/NEMA there is no de-rating

- Low working temperatures down to -25

- Possibility to include any kind of accessories

- Insulation class H

Technology

- Copper foil and wire, Aluminum foil and wire in high voltage winding

- Copper and aluminum foil in low voltage winding

- HV and LV winding winded as a compact and robust block

- Impregnation under vacuum and pressure condition

- Low partial discharge values <10 pC

- Low induction level and step lap configuration granting lower noise level

- High impulse voltage withstand

- High short circuit withstand (radial and axial)

Customized solutions: Meet customer’s various demands

Design options

- Reduced loss transformers

- Copper windings

- Low voltage transformers

- Reduced temperature rise

- Multiple primary voltage

- Multiple secondary windings

- Multi winding transformers

- Different location of high and low voltage connection terminals: top and bottom, both on the same side

- Special connection groups

- Autotransformer

- Variable speed drives ( VSD ), rectifiers and excitation transformers for 6, 12, 18 and 24, 30, 36, 48, 54, 60 pulses

Accessories

- Temperature monitor

- Antivibration pads

- Space heaters

- Electrostatic screen ( copper )

- Current transformers on primary and secondary windings

- Plug in bushings

- High voltage earthing switch

- Surge arrestors ( for high and low voltage )

- Flexible terminals

- Connection box

- Bidirectional wheels

- Different enclosures with cable or bus-duct connection

- Earthing bullets

- Lifting and pulling lugs

- Voltage detectors

- Special packings

- Hydrocoolers

- Cable boxes

- Skids

Testing and logistics: Make sure every product reaches our customer with high quality

All transformers are manufactured to the most stringent quality control standards in order to guarantee the full reliability of the product

Routine test

All transformers are 100% routine tested:

• Voltage ratio measurement and check of phase displacement

• Induced over-voltage withstand test

• Partial discharge measurements

• No load loss and current measurement

• Measurements of windings resistances

• Load loss and short circuit impedance measurements

Type tests

Performed according to customer requirements:

• Temperature rise test

• Lightning impulse test

Special tests

Performed according to customer requirements:

• Measuring zero-sequence impedance

• Noise level test

• Measuring insulation resistance

• Measuring of harmonics of the no-load current

• Measuring of the parallel capacity of windings and tag ∂

• Anti-corrosion protection checking

• Short circuit test Vibration test

Additionally, our transformers comply with the following standards:

• The class F1 “Fire behavior”

• The class C1, C2 “Climatic”

• The class E2 “Condensation and humidity”

Logistics and services

Once the transformer is successfully tested, the product is ready for shipping, either by truck or sea freight.

As a manufacturer, Putuo Electric understands the relevance of what logistics represents to the customers. This is one of the reasons why Putuo Electric has developed a large and qualified network of suppliers with the same values and targets.

Putuo Electric takes care of all official documentation, depending on the final destination and delivery terms.

Different packaging for special applications or conditions

• Standard packaging

• Crate packaging

• Sea-worthy packaging

Putuo Electric has a long experience in arranging special transport, as and when it is required.

In addition, Putuo Electric’s global presence ensures the best, local, and after-sales service.

Working with Putuo Electric, you have access to a worldwide service with a full range of products and solutions, access to production facilities using the most up to date technologies that provides the highest quality for standard and specially made products and solutions. Our warranty provides “Life-long & 7/24” quality and service.